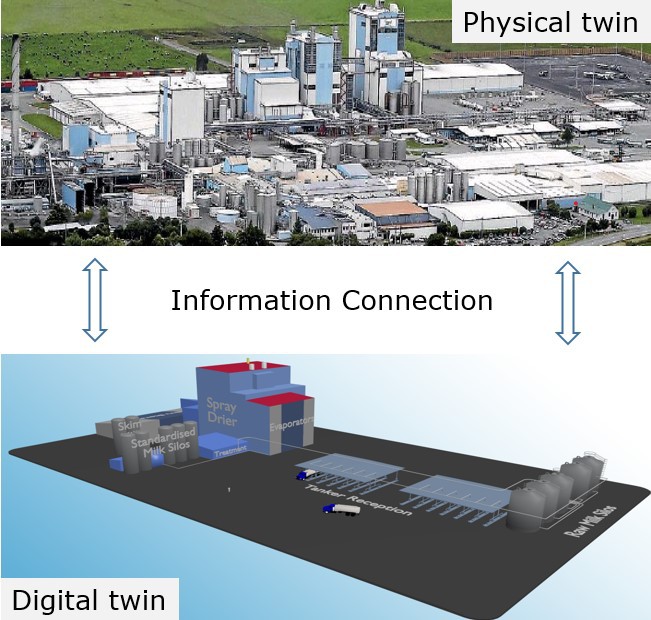

Modelling – creating ‘digital twins’ – was at the heart of how Waipapa Taumata Rau, University of Auckland Professor Brent Young went about working through Fonterra’s challenge. Digital twins are detailed models of factories and processes which mirror their inputs, functions and outputs with a high level of accuracy. Thus, they can predict the effects of certain changes and offer a valuable opportunity to tinker with different variables, with the advantage of being in ‘sandbox’ mode.

“Digital twins allow you to engage in supported thought experiments,” says Young. “You can really stress the system and push it in ways you wouldn’t push the real process because it would be expensive or dangerous to do. Sometimes you come up with really interesting, counterintuitive results.”

Once a digital twin is validated as running realistically, the model follows the laws of physics, chemistry and biology to model what happens when circumstances change. The modelling considers predictable events such as the deterioration of equipment over time, as well as unpredictable ones such as power outages and earthquakes. It can also uncover a myriad of unintended consequences of making certain choices.